what is hardness testing of materials|how to measure surface hardness : manufacturers Scratch hardness is a measure of a material’s resistance to scratching or abrasion. It is used for hard and brittle materials, such as ceramics. It is determined by assessing the ability of a harder material to scratch a softer . webvillavezzane on January 29, 2024: "Gastronomia Villa Vezzane Menus com massas e Churrasco Foto: @studiokfotografiaefilms #gastro."

{plog:ftitle_list}

Resultado da A fase eliminatória da Liga dos Campeões está de volta! Mergulhe nos placares ao vivo, notícias exclusivas e os melhores momentos do ápice do futebol europeu em Flashscore.com.br. Junte-se a nós na jornada para Londres e veja se o formidável Erling Haaland liderará o Manchester City .

What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in .Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the framework of fundamental research (materials science, materials .Materials Engineering. Hardness Testing. Discover the intricate world of hardness testing in materials engineering. This comprehensive guide delves into the definition, standards, . Scratch hardness is a measure of a material’s resistance to scratching or abrasion. It is used for hard and brittle materials, such as ceramics. It is determined by assessing the ability of a harder material to scratch a softer .

In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in .Scratch testing. The hardness of a material can be determined based on Moh’s scale of hardness, which ranks a material based on a list of standard materials with known hardness. The hardness of the material is ranked on the scale between the material it just scratches and the material that it fails to scratch. Moh's Scale of hardness

Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength .

The principle is that an object made of a harder material will scratch an object made of a softer material. When testing coatings, scratch hardness refers to the force necessary to cut through the film to the substrate. The most common test is the Mohs scale, which is used in mineralogy. One tool to make this measurement is the sclerometer. Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. 10 minerals are ranked on the Mohs scale from low hardness to high hardness from 1 to 10 as shown in the below picture. Mohs hardness is not suitable for engineering fields as the hardness of . The hardness of a material is defined as its ability to withstand localized permanent deformation, typically by indentation. Hardness may also be used to describe a material’s resistance to deformation due to other actions, such as: . Rockwell hardness testing equipment. (Source: Sorapol Ujjin / Dreamstime.com) .

Hardness testing is a fundamental material science technique that measures a material’s ability to resist deformation. It is an essential parameter in the manufacturing industry, as the hardness of a material can affect its strength, durability, and performance. The hardness test is a way to assess the quality of a material, determine its . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time). Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . small indentation size can result in poor representativeness and therefore is not suitable for coarse or non-uniform materials. (4) The Rockwell hardness test is divided into various scales, each with a wide .

The test specimens have been standardized by ASTM (American Society of Testing Materials). Engineering Stress Strain Relationship. . What are the advantages and disadvantages of the Brinell hardness test? Advantages: It measures the hardness of a relatively large area, therefore, it is useful in measuring the hardness of inhomogeneous . The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1.

Hardness Testing in Materials Engineering . Hardness testing, as one of the cornerstones of Materials Engineering, is a fascinating area you should delve into. It's an essential quality control process that aids in determining the suitability and sustainability of .

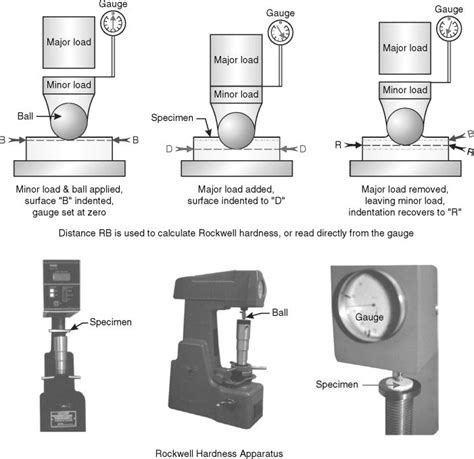

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.For this reason the Mohs test, while greatly facilitating the identification of minerals in the field, is not suitable for accurately gauging the hardness of industrial materials such as steel or ceramics. (For these materials a more precise measure is to be found in the Vickers hardness or Knoop hardness.)Hardness is a characteristic of a material, not a fundamental physical property. . The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this .

types of hardness testing methods

Hardness Testing Basics What is Material Testing Learn about different types of material testing equipment and what you can use them for . Fixtures and Accessories for Material Testing Machines Lloyd material testers offer a wide variety of fixtures and accessories for its material testing machines. They are summarised in the following.

This test method was devised in 1939 by F. Knoop and colleagues at the National Bureau of Standards in the United States. By using lower indentation pressures than the Vickers hardness test, which had been designed for measuring .The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most widely used hardness test. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test provides portability and convenience.

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . Rockwell hardness is determined by measuring the distance traveled by an indenter when a heavy load is applied to a heat treated part. Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . Material Hardness testing measures a material’s resistance to deformation, by pressing a harder material into its surface. It is used in a number of industries for material comparison and selection, as well as quality standards of a manufacturing or hardening process. A specifically manufactured indenter, with chosen dimensions, is used to .

Aside from that, it is suitable for bulk metal hardness measurement. However, the Brinell hardness test is unsuitable for welded joints and hard metals (over 450BHN). Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

principle of hardness tester

WEBMia Khalifa Slot is on Facebook. Join Facebook to connect with Mia Khalifa Slot and others you may know. Facebook gives people the power to share and makes the world more open and connected.

what is hardness testing of materials|how to measure surface hardness